Bearing Plate

Steel disc has thickness over 22mm and three kinds of diameter 30cm, 40cm, 75cm by K.S.F 7444 adjustment it is decided according to all situation.

Implementation of the various inspection of pile

execution plan of pile & specification structural calculation statement depth of pile geologic plan of soil, etc.

As structures are gradually getting huger, these structures's foundation is also getting huger and its importance is increasing. Besides the way to sustain huge structures of the river, river-mouth or seaside was only to drive pile or foundations deeply but development of constructional and design techniques have made possible to construct and design piles and foundations. However, a sure method to make these piles can sustain their design load is to grasp loading ability, soundness and defects of piles and the reflect then on other constructions by strict quality management.

To confirm the stability of a superstructure that will be constructed, this is an important matter, which can't be overlooked. The pile test is the most important work in the construction of a structure because it predicts the whole structure's the expected life span.

Simbat test

Parallel seismic test

Impedance test

Sonic coring test

In constructing cast-in-place piles

1-1) First of all, execute a soundness test of piles by sonic coring test.

Judge if a section of point of the pile is reducing or not, penetration present condition of time and material divisional phenomenon at first, and then determine to use serious piles after Simbat test.

1-2) Cast-in-place pile had better be examined at sixth day after constructing the pile concrete. Because by doing this, we can easily drill a grouting hole that is repaired immediately for the bud that is possibly occurred.

1-3) If the place when we are going to construct cast-in-place piles and concrete is under water but we cannot dam up the water, material divisional phenomenon of the point is inevitable due to disparity of pressures between inside and outside. Therefore, when we construct piles in these places, it is advisable to lay a pipe for grouting under the centers of pipes in advance.

1-4) The sonic coring test has the dead angle Zone, which misses the dispatch and receipt of an ultrasonic. Therefore it had better to lay many tubes as possible as we can or to undergo an impedance test at the same time if the amount of money for laying tubes is a problem.

1-5) When reinforcement by grouting is needed because of a defect of point and something like that, we use the laid tube or drill other boring holes to reinforce. At this time, we prepare an impedance test to provide the case that grout fills up the tube hole.

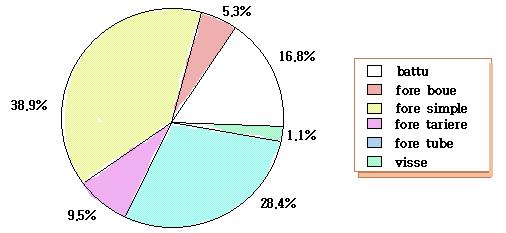

Battage as mentioned above means free falling action with a drop hammer.

On the basis of the wave equation theory (that alias, dynamic model by hitting equation) made a number of pile models about change from dynamic reaction to static reaction and tried out static and dynamic loading test at the same time. data base called Simbat by using comparative solution and consequence solution of two experiments shifted by diverse soil.

Thus, the basic theory of Simbat test (static and dynamic loading test) is formed by reaction survey of pile, which can be measured by giving permanent, weak but continuous movement to head of pile, and comparative analysis about reactions of the pile.

Misung study widely whole parts of test like static and dynamic loading test, soundness,

impact seismic, etc and continuously try out a static and dynamic loading test.

a) Development of pile test and equipment for data acquisition.

b) Unitary software package for data acquisition.

c) Systemic procedure development to decide equal static loading of the pile.

When we penetrate a pile by driving, the method that measures the amount of penetration and

then calculates pile bearing capacity by driving formula gas a big problem in its dependence,

because it simplifies a pile and soil system extremely. To overcome these limits, a lively

study has started since 1930's until mid-1960's. In early 1960's Dr. Smith proposed a new

theory about the way to measure pile bearing capacity by giving force directly to head of pile.

European countries and USA. had introduced the method to research loading ability of

pile on the basis of this theory and started to apply it to piles from the latter half of 1960's.

But, this method also was starting to come out problems, this formula, namely, the method used by substituting drop hammering formula for bearing capacity is not difficult in application of the simple P.C, PHC pile, etc., but it has big problems as the possibility of the trust on large diameter cast-in-place pile of the big unit square measure developed these days and foundation body including various soil.

Namely, it is difficult to understand the loading test accurately as the falling wave velocity

into the pile by established accelerator meter or pile and as the measured deforcement ratio by strain gauge. This method is possible for the certain investigation in falling compressive wave, but not in rising elastic wave.

Move and more the numerical value of the rising elastic wave is different by the pile mobility

of side friction from the reaction of soil, the distribution of the rising and falling wave from

many experimentations is applied in the formula of wave transmit distribution on back pile.

The value of the side friction mobility of pile, the value of displacement of different soil each other, the value of dynamic displacement of ground, namely, Rdy = F (free rising pile) - F (real pile) is got all from the real pile experimentation of 100's. And for making the possibility of trust high, another instrument, namely, as composing strain location by the electric theodolite possible 10-4 measured with the accelerated meter, removes errors of rising, falling velocity caused by various soil. On the basis of various and real experimentation.Simbat test has the new formula of the result of the static reaction U=Ri/kd(1-F/Ri) the first.

The simbat test gives the transition of the static reaction from elastic reaction of soil joint-film reaction, destructive adhesion, namely, the static reaction of pile through study and real experimentation for film of the pyramid of soil. And in 1960, the equation of hammering wave of Dr. Smith, the active model of soil not solved in the estimation of the pile loading test is inserted perfectly into simbat program.

As the method theory of sub question of next page is the result of experimentation from

simbat test, shows all method of impact with the static reactive result of Ray soil and Ep-

Ray graph, and also shows the first and second analysis with the only impact. Anyway, we advise that you can use this method of investigation in making the cost price low, period of work shorten, the perfect investigation of pile loading ability.

▒▒▒ Proposed methodology ▒▒▒

The method that adds (gives) dynamic load on pile as setting bomb for adding physical force on the top of the other pile and dropping freely the drop hammer by explosion is turned its face away in Europe caused by the high-cost and the possibility of danger.

The quantity of bombs is settled by the loading ability of the calculated pile under

design. So if the executed normal state of the pile includes some possibility of badness, the usable pile will be broken by loading test, and it can not be tested many times with

coordinating from low quantity to large caused by the high-cost for setting bomb one time.

And also, the loading test of the simple pile used by substituting the only method of drop

hammering for bearing capacity of pile must be considered as test in the progress of

execution estimated that the normal state of execution of the pile is good or not, and must be considered as problems of the possibility of trust for estimating accurately that the loading ability is good or not.

Early 1980's, France was starting to agonizing about the loading ability test of large diameter pile passed various poor subsoil and bridges between Belgium and Paris.

The Simbat program was developed to solve this problem.

This method was used for the pile loading test of the T.G.V whole section by executing the experimentation about difference of the static·dynamic loading over 100 times according to displacement of soil, and removing the difference of the static·dynamic loading and ending problem of the possibility of trust on the basis of numerical value and geometric theory with putting a graft into various dynamic loading theory like the theory of Dr. Smith, WEAP V. Fioravante of Goble, Rausche, and base part (soil) of Dr. F. MUZZI.

Now, the simbat test is enforcing all over the world, and the actual results is added to an appendix.

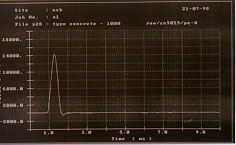

Simbat test is used for dynamic loading test of piles inclusively and through a loading test, we can get a detailed result of blow, data, data procedure for each blow, dynamic resistance of pile and finally static bearing capacity. And two loading abilities to frictional force and static, loading present being in Simbat program.

1) Dynamic loading of piles

Most dropping power of drop hammer affecting on head of pile is out broken by free overfall. The change of generalized drop height is presented by indicating power.

Some ramming units (2t-5t-8t-10t) are used to value equal loading between 500KN and 10000KN. And they measure the pile bearing capacity hitting many times with changing small hammer or height of free overfall to protect pile test. Head of pile has to be prepared to attach mass for hitting and measuring equipment.

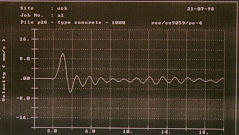

2) To get data

The thing attached on head of pile is composed of two opposite strain gages and accelerometers, and target of electronic theodolite located within 5m from pile. This is to present momentary or permanent displacement.

For each blow dynamic power, acceleration, continuity, displacement of the moment are recorded. The complete test is tried out by applying 10 blows and studying pile movements in strain range. To expect trust in Dr. Smith's theory, interrelation between settlement of the moment and permanent displacement of pile are researched besides the speed which permeates into a pile in the test. And for this research, the physical settlement is inserted into Simbat program and analyzed by fitting with electronic theodolite that can measure until 10-4 in the complete test.

By virtue of High-Strain Dynamic Testing of piles of ASTM D4945-89, the sheet to measuring Set Rebound in Note 6 has to be set up horizontally.

Simbat test is the new method of construction that can measure the displacement occurred by electronic theodolite, to protect 2% error of prescribed signal in ASTM.

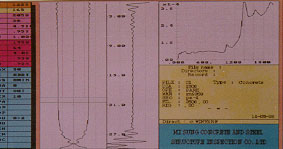

A summary drawing of SIMBAT TEST

< IMPEDANCE REFERENCE >

| Area | Date | A kind of pile | A diameter(mm) | Length(m) | |

|---|---|---|---|---|---|

| Chellea(Fr) | 94/ 10/ 10 | concrete | 1000 | 12.50 | |

| La Haye les rosesl | 97/ 12/ 10 | concrete | 400 | 11.00 | |

| Sete | 93/ 03/ 02 | concrete | 600 | 13.00 | |

| Nancy | 91/ 05/ 23 | concrete | 500 | 12.00 | |

| Vancouver | 91/ 04/ 02 | concrete | 1000 | 15.00 | |

| Montreal | 91/ 07/ 16 | concrete | 700 | 16.50 | |

| Montgru-saint-hilaire | 94/ 03/ 10 | concrete | 350 | 13.80 | |

| Belgium | 96/ 11/ 23 | concrete | 2000 | 37.50 | |

| Netherlands | 97/ 09/ 25 | concrete | 1500 | 32.00 | |

| Spain | 96/ 10/ 10 | concrete | 1100 | 35.00 | |

| France(A rapid-transit railway) | 90/ 08/ 07 | concrete | 1200 | 42.00 | |

| China(Tianjin) | 2007 | concrete | 1000 | 45.00 | |

| Korea (Including Sonic coring & simbat test) |

A port of Busan | 94/ 08/ 08 | concrete | 1500 | 42.00 |

| Gwangandaegyo Bridge | 1996~1998 | concrete | 1500 | 43.00 | |

| Gwangandaegyo Bridge | 1996~1998 | concrete | 2200 | 43.00 | |

| Samrangjin Bridge | 2002 | concrete | 1500 | 47.00 | |

| Ungcheon Bridge | 2002 | concrete | 1500 | 48.00 | |

| Incheon Bridge | 2005 | concrete | 1500, 2000, 2500 | 30.00~45.00 | |

| Eulsukdo Bridge | 2006 | concrete | 1500 | 92.00 | |

| Angol Bridge | 2012 | concrete | 2500 | 45.00 | |

< SISMIQUE PARALLEL TEST REFERENCE >

| Area | Date | A kind of pile | A diameter(mm) | Length(m) | |

|---|---|---|---|---|---|

| Paris | 94/ 06/ 03 | concrete | 800 | 15.00 | |

| Italy | 95/ 06/ 05 | wood | 300 | 13.00 | |

| Vancouver | 96/ 07/ 10 | concrete | 750 | 18.00 | |

| Crale | 96/ 12/ 11 | concrete | 1000 | 32.00 | |

| St-Remy | 97/ 01/ 15 | concrete | 900 | 20.00 | |

| Spain | 97/ 03/ 12 | concrete | 750 | 25.00 | |

| Belgium | 97/ 05/ 25 | concrete | 1500 | 35.00 | |

| Korea | Seoul | 97/ 09/ 09 | concrete | 450 | 22.00 |

| Gyeongsangnam-do | 2001 | concrete | 1500 | 40.00 | |

| Busan | 2006 | concrete | 1500 | 40.00 | |

| Busan | 2008 | concrete | 400 | 36.00 | |

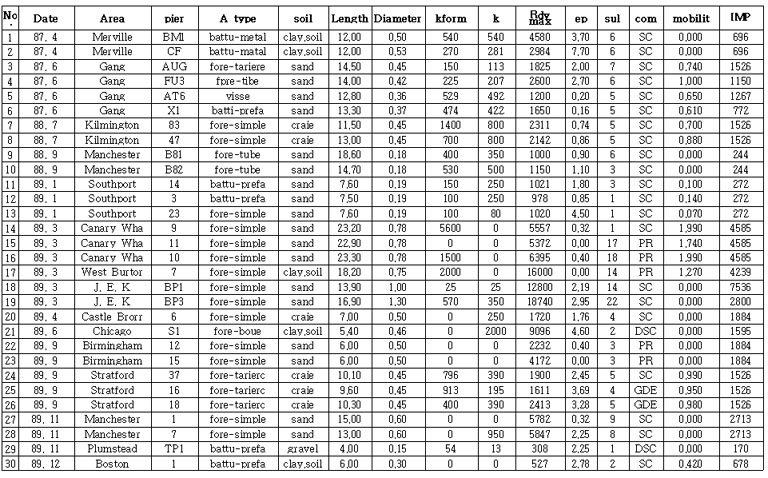

Eulsukdo Bridge SIMBAT TEST test result data (2005.09)

* Result value by dynamic load by hit height

(weight of pendulum : About 10Ton, Jc = 0.25)

Ft, ZVp, and Estimated static reaction values are applied to the force separation graph in the attached document.

In addition, the soil quality factor Jc value according to the soil condition was calculated by considering the soil around the piles as one special medium. That is, the calculation of the Rstat value considering the Jc value gave the Jc value to the Rdy and ZVp values and the Jc value range (0.05-1.10) described in the previous length. At this time, the value of the maximum intersection point of the straight line was calculated as the representative soil value around this pile, and the Jc value obtained at this time was 0.25.

No.(HittingNo)

Hitting height(Cm)

Rdy(KN)

Rshaft(KN)

Rtoe(KN)

Ft(KN)

Zvp

Equivalents Rstat(KN)

1(12)

160

18046.27

17400

646.27

22000

16373.68

13953.10

2(13)

200

20396.57

19400

995.57

25000

17492.29

16022.50

3(14)

250

17891.12

17400

491.12

23000

17230.87

13584.65

4(15)

200

21363.32

21000

363.32

25000

18471.24

16746.51

5(17)

300

23346.79

23000

346.79

29000

21539.89

17961.07

6(19)

350

27436.27

26800

636.27

32000

24701.89

21260.80

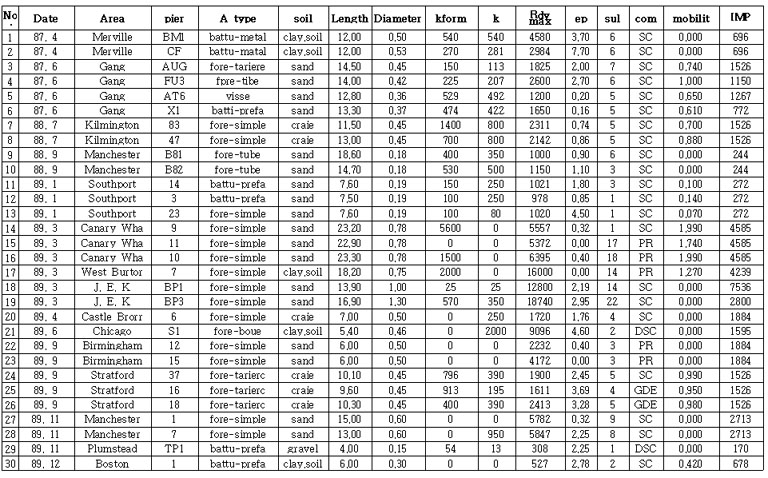

* Result value by static load by hit height

(weight of pendulum : About 10Ton, K≒7000)

K represents the ratio of the amount of change in the amount of settlement to the change in the dynamic reaction force, and the slope was calculated from the ΔRdy/ΔEp curve to calculate the Rstat value by the Simbat method.

As a result of the analysis, the Rstat by the Simbat method showed the highest value at the hitting height of 350cm, and the Rstat value at this time was 21836KN.

No.(HittingNo)

Hitting height(Cm)

Rdy(KN)

Ep(Cm)

Rstat(KN)

1(12)

160

18046.27

0.05

17696

2(13)

200

20396.57

0.20

18996

3(14)

250

17891.12

0.30

15791

4(15)

200

21363.32

0.15

20313

5(17)

300

23346.79

0.30

21246

6(19)

350

27436.27

0.80

21836

* Conclusion to the test

When the maximum impact load was applied (H=3.5m) as a result of carrying out static and dynamic retesting of one P9-1 cast-in-place pile in the Eulsukdo Bridge construction site, Rdy is 27436.27KN, at this time Rshaft is 26800KN and Rtoe is 636.27. As for the static loading force due to dynamic loading, the Estimate Reaction value on the Data Base in the SIMBAT Program was 20025.71KN, and the equivalent static load mobilized value considering the soil condition was 21260.80KN. Meanwhile, 18.0mm of permanent settling occurred until the final driving.

[Unit KN(ton)]

※ In the static and dynamic loading test by Simbat test, reliability is considered when the Rstat(Jc) by dynamic loading and Rstat(K) by static loading show a deviation within 10%. (The error range of the correction compared to the dynamic loading test after the static loading test when creating Simbat program). As a result of this test, the deviation of these is about 2.63%, and it is judged that the reliability of this field test result is high according to the study result by Simbat simulation.

Total dynamic Reaction

Static Reaction

Ep(mm)

(Permanent settlement)

Rdy

(Total dynamic reaction force)Rshaft

(Principal plan frictional force)Rtoe

(Point bearing capacity)Rstat

(Jc)Rstat

(K)

27436.27

(2797.72)26800

(2732.84)636.27

(64.88)21260.53

(2167.97)21836.00

(2226.65)18.0

Based on the above results, when calculating the allowable bearing capacity

● Review of bearing capacity

- Design bearing capacity = normally 884.0 ton, In case of earthquake 1175.0 ton

- Dynamic bearing capacity Rdy = 2797.72 ton

- Static bearing capacity Rstat = 2167.97 ton

● Review of settlement amount

DIN 4026 criteria(Settlement amount standard) : 20mm (in-site pile)

Based on total settlement amount : 0.1D = 150mm(in case of ultimate load)

Permanent settlement amount during test = 18.0mm

※ The results of this test were not separately reviewed for the safety factor.

Item/Pile No.

Settlement amount

Bearing capacity

Settlement amount(mm)

Standard settlement(mm)

Judgment

Dynamic bearing capacity(ton)

Static bearing capacity(ton)

Design bearing capacity(ton)

Judgment

P9-1

18.0

20

O.K

2797.72

2167.97

884.00

O.K

1175.00

Comparison for a existing static and dynamic loading test with Simbat test

The dynamic loading test to use frequently nowadays

i) CASE METHOD : Loading capacity test by a hitting equation basis on Dr. Smith's wave delivery theory in 1960

ii) New-Matic Dynamic load test : The test that sets up an explosive on the basis of a hitting equation and then gives dynamic loading by that explosive power.

If soil quality of earth is simple and a pile is short diameter steel pile, P.C or P.H.C, we have measured penetration of the pile by a hitting equation and probed point of pile bearing with a exacting method of construction, but now, there are many problems to apply a hitting equation due to change of soil quality and cast-in-place pile. Especially, cast-in-place piles differ from an experiment with a hitting equation theoretically because cast-in-place piles are constructed by the method that penetrates piles with boring.

Simbat test is produced by complementing these problems.

- Comparison for Simbat test with the existing loading test

| Scope of measurement | Static loading test | Dynamic loading test | |

|---|---|---|---|

| Case Method | Simbat Method | ||

| Measurement of sink quantity | yes | no | yes |

| Measurement of degree of acceleration | no | yes | yes |

| Velocity to correct | no | no | yes |

| Simulation of dynamic a state of effect | no | yes | yes |

| When load acting, load control to effect in pile | no | no | yes |

Conclusion

After we tested Simbat test for 3 years, Simbat test has been used very much. ; Other units applied for other piles were used. Data is gotten and analyzed by micro-computer and to explain data is concluded in combined Simbat program. Simbat test have been used in other parts due to change of piles, so we press it into the service of P.C, PHS, steel pile and sheet pile, etc.

In the condition that to approach to head of pile is no longer possible because of upper structure and there are few other non-destructive test worth being used, a doubt about the length and degree of completion of piles has occurred. In this condition, many kinds of test were studied to inspect the length and soundness of a pile, and we tried out the parallel elasticity wave test with transformation the inspecting method by seismic

This is a method to inspect by hitting the head of pile and foundation part. The vibration wave inspects a condition of pile with analyze time of signal conveyed up to receipt sense inside of tube passing the pile.

- A tube, closing up a tip, is fitted out so as to be level with an axle of a pile. And drive deeply at least 2m or more than maximum lean expected.

- We encourage using a tube made of ABS plastic.

- A tube has to be able to drain water off and to attach to around ground. This means that bentonite or cement grouting is done after insert the tube.

- Tube has to equip on the place that is distant at most 400mm from where will be inspected.

-Inside of a tube is filled with water.

-A great distance sensor has to be lower than a foundation of the tube raised 0.5m∼1.0m. In each of rises a pile and a structure are hit by equiped hammer and signal is transmitted from a hammer to a sensor and recorded.

- Outline of transmitted signal is planned and arrival time of signal is indicated.

This equipment for test is composed of a great distance sensor, geophone, accelerometer, seismic inspection device and a hammer having a damping device inside and data acquisition-system.

Contents following have to be included in the report of this test

- Shapes of all transmitted signals of each of piles.

- Types of piles, soil condition and the way to test have to be included in detail.

- A chart about the result produced according to given numbers of piles, a Data related to depth.

- Data related with record of lean.

- Pile soundness survey

- Pile depth of embedment

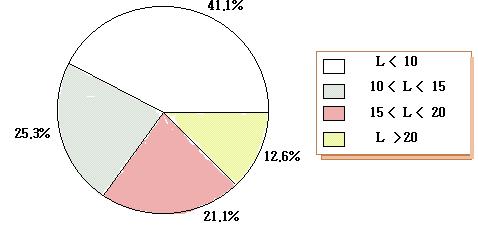

Sonic coring test is a technique developed in 1960s, and it began to be explained by Levy and applied in 1975, Paquel and Briard announced a result of sonic coring test by means of the data gotten by piles for test that had to be constructed with confirmed defects, and after that, the method took effect widely. Misung use to test a homogeneity of concrete of a pile and bulkhead and soundness at domestic construction job-site.

In sonic coring test, laying a needed vertical tube under the ground is necessary because before the test the construction company should take down a transmitter and a receiver of the sound wave until the depth in which a pile is.

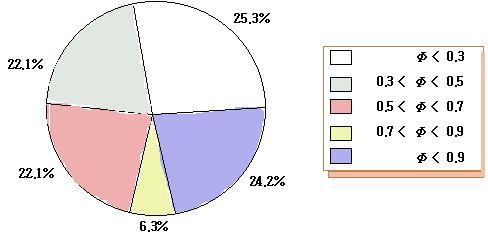

- Select the number of tube, the range of laying tubes under the ground and the way to lay firmly.

- Tube minimum number according to pile diameter

| classification | tube number | remarks |

|---|---|---|

| Φ ≤ 0.6m | 2 | |

| 0.6 ≤ Φ ≤ 1.2m | 3 | |

| 1.2 ≤ Φ ≤ 1.5m | 4 | |

| 3.0m ≤ Φ | 5 |

|

|

|

|---|---|---|

0.6≤Φ≤1.2m tube three |

1.2m<Φ≤1.5m tube over four |

over Φ3.0m tube minimum 5 |

An engineer for test should give the information about condition of concrete, abnormality of a pile to the engineer of a construct company immediately. And when about 7 days passed since a pile had laid to test the pile is advisable.

This is because later, it is easy to be a mechanical coring in that condition when we repair the pile and the time taking to be the condition that transmission and reception of ultrasonic waves are easy is 6∼7days.

An engineer for test should have extensive knowledge about concrete construction. He should grasp the non-homogeneous condition and advise to correct constructer's mistakes.

If a tube is not laid under the ground more deeply than concrete point, testing for the point is impossible. Because of not laying the range of province on transmission and receipt but to execute with decreasing the cost, a dead angle zone of the investigation range from ultrasonic waves comes out.

Traditional way including a strict quality control of concrete and select load test of pile is being generalized. However, due to the loading test is generally so expensive, we have no choice but to test only one or two selected pile.

In an ideal condition, this is enough but because of variable circumstance of the earth and problems of construction, there may be problems following.

First - Necking and arching occurred in concrete when we remove a steel pile added specially.

Second - Necking and arching occurred in collapsed side wall.

Third - Soft toe occurred by collapse of side wall or dirty lower part.

Fourth - Separation appearance of a horizontal layer of silt, mud and bentonite occurred in case of falling upper concrete tremie pipe that come up upper concrete.

Fifth - Voids occurred by using the concrete that doesn't go down well.

Sixth - Honeycomb occurred with micro material is wiped.

Because sonic coring test can find this, all kinds of non-homogeneity and the price is not expensive, it is very practical. However due to there is a dead angle that strays from beeline band, we must refer to quality test

|

|

|

|

Rigid concrete quality management and typical methods including selection pile loading test are very popular but loading test is too expensive so it's tested selected pile.

1) Theoretical background of Sonic Test

|

① V (Velocity) : velocity of wave through medium ② L (Distance) :distance between two points (distance between tube) ③ T (Time) : arrival time ④ E: dynamic modulus of elasticity of medium ⑤ υ: dynamic poisson ratio ⑥ ρ: density Tube distance : 40cm ∴ Japan Architecture Institute Fc = 215 Vp - 620 ∴ Deduction compression strength Fc = 177 Vp - 476 = 202 - 574 Therefore it's very useful if checking defect part at projection chart photographing and comparing with velocity this part and normal part |

⑴ Emission probe

Important condition for emission probe is ① solid ② clearness of ultrasonic sound

③ It can be strong even though low voltage for preventing outside intervention

⑵ Reception probe

Contact surface of concrete and water concentrate ultrasonic and the power gather at one point back center of tube.

- Defect type of vertical part

| Inspection date : May 28 1999 (First TEST) | Unit : M |

|---|---|

| TRACE 4-1 | TRACE 4-1 |

|

|

|

|

|

|

| Inspection date : May 28 1999 (First TEST) | Unit : M |

|---|---|

| TRACE 4-1 | TRACE 4-1 |

|

|

|

|

|

|

|

Aggregate segregation at vertical point |

| Inspection date : June 21 1999 | Unit : M |

|---|---|

| TRACE 2-4 | TRACE 2-4 |

|

|

|

| Inspection test : Sep. 14 1999 | Unit : M |

|---|---|

| TRACE 4-1 | TRACE 4-1 |

|

|

Void generating by moving underground water of pile center part |

|

|

|

|

| Inspection date : Nov. 3 2000 | Unit : M |

|---|---|

| TRACE 1-3 | TRACE 1-3 |

|

|

|

|

| Inspection date: Nov. 3 2000 | Unit : M |

|---|---|

| TRACE 2-3 | TRACE 2-3 |

|

|

|

|

Strength drop by concrete deterioration |

|

|

| Inspection date: March 27 1999 | Unit : M |

|---|---|

| TRACE 2-3 | TRACE 2-3 |

|

|

|

|

| Inspection date: March 27 1999 | Unit : M |

|---|---|

| TRACE 2-4 | TRACE 2-4 |

|

|

NECKING by casing pull-out's badness |

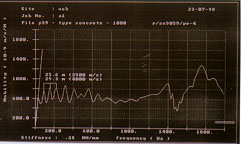

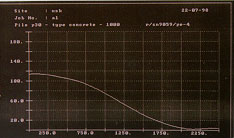

Impedance test is big change of density to the direction of impact under adding short impact to anybody of target and is the test out length of pile or depth of defect after seismic of wide frequency part including ultrasonic's zone measures reflective signals reflected back by foundation part of structure or defects of internal pile.

Because in ordinary concrete, the ultrasonic passing inside of concrete proceeds at speed of 4000m/sec if the age is 28 and 3500m/sec if the age isn't more than 28, impedance test shows a change of density, that occurs when foundation pile or concrete structure is given a short shock, and after capture a wide frequency band including ultrasonic band, express it by graph. And this graph is expressed by mobility, velocity, force and force spectrum. Also in the gross of these, mean mobility graph must be able to be described and defects of a pile, seismic force, stiffness value of supporting point (shift of K) have to be cased and described a length shape of defects and a length of a pile. Besides, a recorder of machinery and tools have to be able to show four kinds of graph.

Check the shape of pile by elasticity wave and use as data for final judgement.

The important facts of loading test for bearing force of soil test of constructing lower part and loading test of small pile except Simbat Test are as below.

The load method is divided into actual loading test and resistance as Achor.

|

|

| (a) Pile loading test by actual load (application to small pile) | (b) Pile loading test using surrounding pile's reaction |

Steel disc has thickness over 22mm and three kinds of diameter 30cm, 40cm, 75cm by K.S.F 7444 adjustment it is decided according to all situation.

Hydraulic jact (50ton capacity)

Graduations for measuring : 0.01mm

Movement of frog at one revolution : 1mm

Maximum moving amount of frog : 30mm

50mm displacement machine (digital)

Assistance supporting sticking dial gage

Load by dead weight of digger using hydraulic (Real loading is done actual loading like mat pile but ample digger is used for simple and convenient loading.)

Program for displacement measurement

Interior computer

STA Program/SAS 97

Arrangement of pile head and ground must to be done very carefully because result of loading test is reflected to transformation of pile head and horizontal maintenance. And pay attention not to transform the pile head during test.